Sustaining Improvement

In a couple of recent blog posts (here and here), I discussed the use of daily huddles to help staff in ambulatory surgical centers maintain focus on safety methods like surgical checklists. We introduced the daily huddles using the Model for Improvement, to specify aims, measures, changes and test cycles.

Our work with the ambulatory surgical centers is an application of research summarized in an IHI whitepaper “Sustaining Improvement” published on 3 June (Scoville R, Little K, Rakover J, Luther K, Mate K. Sustaining Improvement. IHI White Paper. Cambridge, Massachusetts: Institute for Healthcare Improvement; 2016, http://www.ihi.org/resources/Pages/IHIWhitePapers/Sustaining-Improvement.aspx.) From a literature review and interviews with leading healthcare organizations, we connect Juran’s perspective on Quality Control with the practice of standardized work for managers that is integral to Lean production systems.

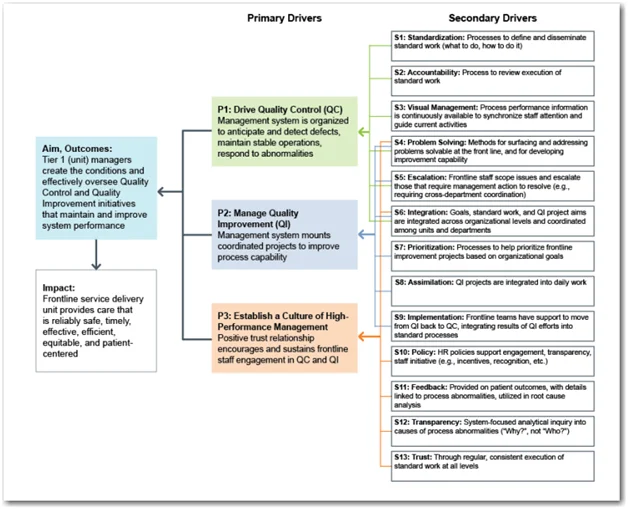

We summarized the drivers of an effective first-tier management system in a diagram (p. 12):

Daily huddles are a way to practice drivers S1 and S2, which in turn contribute to a management system that is organized to anticipate and detect defects, maintain stable operations and respond to abnormalities.